Absolute Pressure Transmitters

Absolute Pressure Transmitters

Pressure Transmitters

Differential Pressure Transmitters

Differential Pressure Transmitters

Absolute Pressure Transmitters

Yokogawa EJA510E In-Line Mount Absolute Pressure Transmitter

Gauge Pressure Transmitters

Introduction to Pressure Transmitters

Pressure transmitters serve as vital instruments in a broad range of industries, providing real-time data essential for maintaining quality control, ensuring safety, and optimizing efficiency. By converting pressure signals from fluids or gases into standardized electrical outputs, these devices underpin everything from petrochemical production to food and beverage processing. Their reliable performance helps avert process deviations, reduce downtime, and meet stringent regulatory demands.How Pressure Transmitters Operate

In general, a pressure transmitter incorporates:- Sensing Element A diaphragm or similar component flexes in response to changes in pressure. Depending on the transmitter’s design, this may be measured via capacitive, piezoresistive, or strain gauge methods.

- Fill Fluid or Isolation System Process pressure is often transferred through a fill fluid to protect internal electronics from harsh or corrosive media.

- Signal Processing Electronics The electrical signal derived from the sensor is amplified, linearized, and converted into industry-standard outputs, such as 4–20 mA or digital fieldbus protocols (e.g., HART, PROFIBUS).

- Protective Housing The entire assembly is enclosed within a rugged shell or casing to shield electronics from humidity, dust, and temperature extremes.

scs-Instrument’s Portfolio of Pressure Transmitters

At scs-Instrument, we source world-class pressure transmitters from established manufacturers to address a wide spectrum of industrial applications. Below are some of the models we proudly distribute:Rosemount 2088 Pressure Transmitter

- Compact, Lightweight Construction for easy mounting

- Proven Sensor Technology ensuring dependable performance

- Wide Range Capability to tackle low and medium pressure tasks

Rosemount 2090 Pressure Transmitter

- Flush-Mount or Sanitary Design ideal for hygienic processes

- Minimal Dead Volume reducing risk of contamination or buildup

- Streamlined Configuration supporting a variety of clamp and flange connections

Rosemount 3051S Pressure Transmitter

- Scalable Architecture that can adapt to future process needs

- Premium Sensor Module offering top-tier accuracy and stability

- Comprehensive Diagnostics designed to optimize uptime and reduce maintenance costs

Rosemount 3051C Pressure Transmitter

- Flexible Platform enabling measurement of gauge, absolute, or differential pressure

- Advanced Digital Protocols (e.g., HART or FOUNDATION Fieldbus) for integrated control

- Stable Performance suited for demanding temperature or environmental conditions

Rosemount 2051C Pressure Transmitter

- Cost-Effective Solution without sacrificing overall reliability

- Coplanar Technology supporting simplified installation and integration

- Intuitive Local Interface assisting in calibration and quick parameter checks

Rosemount 2090P Pressure Transmitter

- Polished Diaphragm Surface suitable for sanitary or corrosive applications

- High Chemical Resistance preventing product degradation or sensor damage

- Easy-to-Clean Design beneficial for stringent hygiene standards in food, pharma, and biotech

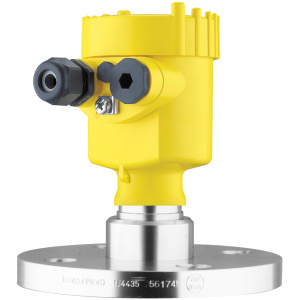

E+H Cerabar PMC71 Pressure Transmitter

- Robust Ceramic Sensor offering excellent abrasion and corrosion resistance

- Modular Configuration for diverse process connections and output signals

- Reliable Accuracy even under rapid fluctuations in process pressures

Yokogawa EJA530E Pressure Transmitter

- Durable Body Construction engineered to withstand extreme process or climatic conditions

- High-Speed Response vital for processes requiring close control or quick adjustments

- Multi-Protocol Compatibility ensuring seamless integration into modern industrial networks

Yokogawa EJA118E Pressure Transmitter

- Specialized Diaphragm Design for level measurement in pressurized or vacuum vessels

- Superior Sealing and Isolation preventing cross-contamination in critical applications

- Long-Term Stability reducing recalibration frequency and lifecycle costs

Advantages of Implementing Pressure Transmitters

- Process Efficiency Accurate pressure data reduces energy usage, product waste, and rework by keeping operating conditions optimized.

- Enhanced Safety Early detection of abnormal pressure variations can safeguard personnel and equipment by preempting dangerous incidents.

- Regulatory Compliance Whether in Chemical & Pharmacy, Oil & Gas, or Food & Beverage, dependable measurement tools help meet stringent industry standards.

- Lower Maintenance Requirements Modern transmitters often include diagnostics that streamline troubleshooting, ensuring minimal downtime and fewer unexpected failures.

- Flexible Installation With multiple connection types, output options, and mounting configurations, these transmitters fit into both existing and newly designed process setups.

Typical Applications and Industry Sectors

Pressure transmitters are essential in:- Petroleum Refining: Monitoring distillation column pressures and ensuring stable product flow

- Wastewater & Sewage: Regulating pumps, controlling aeration, and optimizing treatment stages

- Food & Beverage: Overseeing filling lines, pasteurization systems, and fermentation tanks

- Biotech & Pharmaceuticals: Maintaining consistent chamber or reactor pressures for precise production yields

- Chemical Processing: Managing reaction vessels, pipelines, and storage tanks with corrosive or volatile substances

Troubleshooting and Maintenance

Even reliable devices can face occasional hiccups:- Unsteady or Zero Output

- Inspect loop power, wiring, and grounding.

- Check for clogged impulse lines or damaged diaphragms.

- Calibration Drift

- Compare the transmitter’s readings with known reference points or calibrators.

- Look out for temperature extremes, vibration, or chemical buildup.

- Mechanical Deterioration

- Evaluate gaskets, O-rings, and diaphragms for signs of wear.

- Replace any compromised parts as recommended by the manufacturer’s manual.

Rely on SCS-Instrument for Your Pressure Measurement Needs

Navigating the world of pressure transmitters can be complex, especially with the multitude of product variations and configurations available. At SCS-Instrument, we leverage our in-depth understanding of industrial processes to recommend the most suitable models for your unique requirements. Our focus is on delivering practical solutions that enhance safety, efficiency, and reliability.Why Choose SCS-Instrument?

- Expert Recommendations: Our knowledgeable team is equipped to assist you in selecting the right pressure transmitter from a variety of trusted brands, including Rosemount, Endress+Hauser (E+H), and Yokogawa. Each brand offers unique features that cater to different industrial applications.

- Comprehensive Product Lineup:

- Rosemount Pressure Transmitters: Known for their reliability and accuracy, Rosemount transmitters like the 3051 series are designed to meet rigorous industry standards. They feature advanced diagnostics, Bluetooth connectivity for easy configuration, and robust construction suitable for harsh environments.

- Endress+Hauser (E+H): Their Cerabar PMP series provides excellent performance in hygienic applications with features such as a compact design and high accuracy. These transmitters ensure safe measurement of liquids and gases while offering easy setup and operation.

- Yokogawa Pressure Transmitters: The EJA series, equipped with DPharp sensor technology, delivers high reliability and accuracy across various process conditions. These transmitters are designed for both differential and static pressure measurements, minimizing the need for multiple devices.